5 years of university projects

I studied at Aalborg University, where, generally, student projects make up approximately half of the ECTS points and are completed in groups. This was the case for my education too; I’ve been apart of 10 nerdy university projects which I want to share some details on, now that I have graduated.

For the record, I have studied the following:

- BsC in Electronics and IT

- MsC in Control and Automation

The first has since been renamed to Elektronik og Systemdesign, but I could not find the english name. The second education no longer exists, but most of the courses and projects seem to be available through the Electronic Systems education.

A small preview of every project I worked on at Aalborg University.

1st & 2nd semester - Small beginnings

As is tradition, the first group project was the creation of an autonomous line-following robot and subsequent participation in the RoboCup competition.

We won 2nd place at the competition, awarding us some beers down in DE-Klubben (where I would spend many more semesters). Below is a video of us completing the track prior to the competition.

The next two semester very much focused on methodology, which of course is very fundamental knowledge for the rest of the study period.

Our second project was an analysis of air pollution and the construction of a air quality measurement station, capable of measuring PM2.5 and ozone concentration.

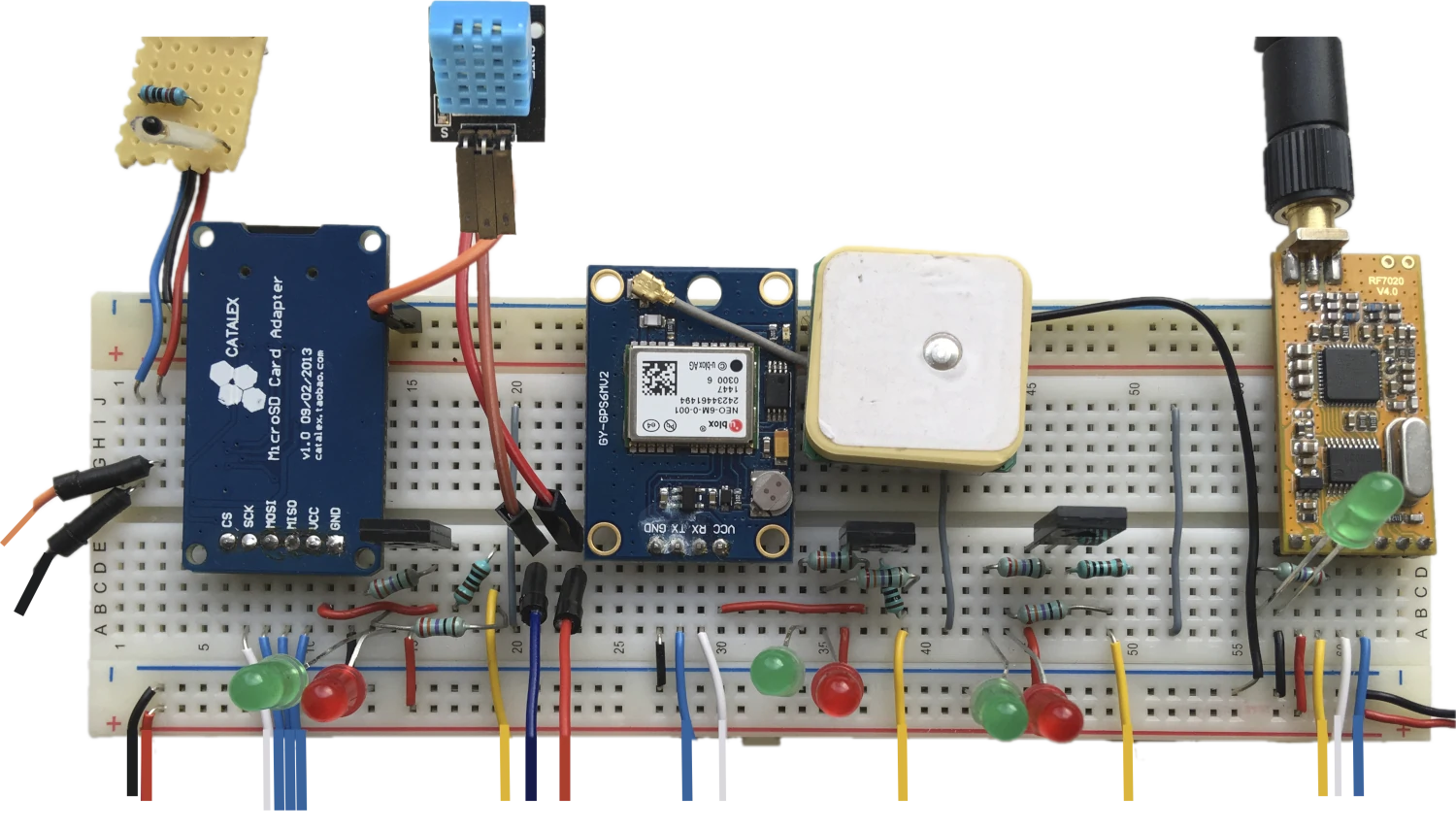

Breadboard of the air quality measurement station. From left-to-right: thermistor, micro SD adapter, air humidity sensor, GPS & antenna and wireless module.

The third project was more of the same, and the end result was functional, but not pretty. We analyzed traffic accidents between cyclist and trucks and developed a circuit with ultrasound emitter and receiver and a filter, which was mounted on a motor to “scan” for bicycles. Looking back, it was simple stuff, but everyone starts somewhere.

The ultrasound scanner, before mounting it on the motor.

3rd & 4th semester - Electronics galore

Following traditions, 3rd semester saw us developing some sort of analogue amplifier. Specifically, we decided to develop a low-noise amplifier for a record player.

All the components used in playing a vinyl.

In the picture above, disregarding the two voltage sources, the components are from left to right:

- The record player, with no active amplification.

- The pre-amplifier which amplifies the signal to line level and applies a RIAA-correcting filter

- A switch for switching between record player and phone line in.

- The main amplifier raising the signal from line level to appropriate speaker level.

- The passive speaker, which plays the audio.

This was the perfect way for us to learn about transistor theory, and a perfect way to create some enemies by blasting Painter Man on vinyl on repeat for a whole semester.

While 3rd semester was completely analogue, 4th semester was completely digital. On an FPGA we developed a small-scale CPU and our own programming language, that we then used as a sort of PLC. To this end, the CPU had some very niche operations for interacting directly with hardware.

We also made an assembler for our language and called it eitasm. Below is an example of how eitasm can compute Fibonnaci numbers on our very own CPU.

|

|

5th & 6th semester - New areas

On my 5th semester, we worked on a control system for a proof-of-concept industrial ironing machine in collaboration with the company JENSEN.

The proof-of-concept ironing machine we created a control algorithm for. We were the first and last group to use it.

In their traditional ironing machines, the clothes are fed between a hot piece of metal and an ironing board in the shape of a barrel. In this machine, the clothes are emulated by cold water through hoses on the right side of the three panels, while the hot metal is emulated by the hot water produced and transported by the heated pump on the left. The hot water and cold water then exchange heat through tubes in the panels.

It might seem like a far stretch, but it really isn’t. During this project, we did a lot control theory which I would later pick as my masters degree.

For my 6th semester, I flipped it around and played around in the realm of signal processing. The project was mainly theoretical, exploring how good different modulation schemes would work for communication between a low-earth-orbit satellite and a ground station.

We then implemented some of these modulation schemes on actual hardware, emulating the distance between satellite and station with signal attenuators. Our algorithms were created with GNU Radio and ran on USRP B210 SDR. It was a cool project, but I don’t think I have any cool images to show that wouldn’t require 5-6 paragraphs of explanation.

7th & 8th & 9th semester - Control and NDA’s

On my 7th semester, we were granted full control of a heating- cooling and air condition (HVAC) system in a room on campus.

A perspective image of our lab with labels. Click here for full resolution.

The general idea was to use the giant water tank in the back as energy storage - when power was cheap, we would heat the water in the tank, and when it was expensive, we would use the heated water.

The actual control algorithm was a lot more sophisticated than this of course, and in the end we did end up saving some money ina real-life scenario (albeit very little). The project was sadly plagued by many practical problems with the laboratory, but it was a fun project nevertheless.

My 8th semester was in collaboration with wind turbine company Vestas. I have signed a non-disclosure agreement, so I sadly cannot share what I worked on.

The same is true for my 9th semester in collaboration with Turf Tank, a company that specializes in autonomous line-painting robots for sports fields.

From the future

From the future

10th semester - Tying it up

My 10th semester was in collaboration with the refrigeration and air conditioning company Bitzer SE (Danish department). This project was a more theoretical, but also a lot more in-depth version of the one on 7th semester.

This time, we were dealing with an entire house with access to ground pipes for heating water, a heat pump and a water tank for energy storage. We were supplied a copious amount of data from sensors inside the house, and constructed and fitted model with subspace identification.

Once we had a satisfying model, we created a controller for keeping a steady temperature in the house. This controller was a model predictive controller (MPC) and took into account the model we just created and outside disturbances such as temperature, continuously solving a quadratic problem to determine how much heating was needed.

We then created a new MPC which also observed the forecast electricity price and saw how it started utilizing the water tank to charge and release energy depending on the forecast. Our simulations showed up to 8% reductions in energy costs for the house, but we had a lengthy discussion segment detailing why it would be less in practice.

It was a great project to wrap up my masters, as it had a lot of advanced control theory concepts. Sadly, I don’t think I have any awe-inspiring pictures here either, so I will leave you with this scene we were referring to daily:

Conclusion

I had a really great time with my projects at Aalborg University. They really were my favorite part of my education, even though some of them were very simple in retrospective.

Published 18. May 2023

Last modified 2. December 2025